品質保證

主要質量保證設備Set

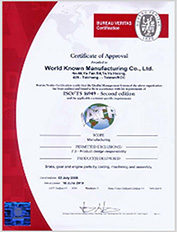

光隆公司於2002年取得ISO/TS 16949的認證,我們的APQP團隊受過專業的訓練,熟悉體系的五大工具和8D手法的應用,確保產品開發從規劃設計階段到驗證量產出貨,所有參與人員完全了解客戶所有需求,並且持續改善,達到顧客滿意的宗旨與承諾。

光隆公司於2002年取得ISO/TS 16949的認證,我們的APQP團隊受過專業的訓練,熟悉體系的五大工具和8D手法的應用,確保產品開發從規劃設計階段到驗證量產出貨,所有參與人員完全了解客戶所有需求,並且持續改善,達到顧客滿意的宗旨與承諾。

APQP 先期產品品質規劃 ( Advanced Product Quality Planning)

FMEA:失效模式影響分析(Failure Mode and Effects Analysis)

MSA:測量系統分析(Measurement System Analysis)

SPC:統計制程管制(Statistical process control)

PPAP:生產件批准程式(Production Parts Approval Process)

| 1 | CE Meter | 2 |

| 2 | Optical Spectrum Analyzer | 1 |

| 3 | Sand Testing Device | 1 |

| 4 | Sandcore Analyzer for gas emit ratio & melting point | 1 |

| 5 | Metallurgical Microscope | 2 |

| 6 | Ultrasonic Tester for NDT & Nodularity (Olympus) | 1 |

| 7 | Brinell Hardness Tester (HB) | 2 |

| 8 | Rockwell Hardness Tester (HRC) | 1 |

| 9 | Universal Testing Machine | 1 |

| 10 | CMM Coordinate Measuring Machine | 3 |

| (1*Zeiss, Germany, 1*Global, USA, 1*Mitutoyo, Japan ) | ||

| 11 | Profile Projector |

1 |

| 12 | Surface Roughness Measurement (Hommel, Germany) | 1 |

| 13 | Cleanness Tester | 1 |

| 14 | Surface Profilometer | 1 |